Stone Crushers: A Technical Review on Significant Part of

2022.5.14 Stone Crusher is a sort of pulverizer which is utilized to compress or break out assortment of enormous stones. It normally highlights a huge crushing rate and high return and is utilized as an essential equipment in primary, secondary, and tertiary stages

More

Stone Crushers: A Technical Review on Significant Part of

2022.5.13 Crushers are one of the essential quarrying machines used in foresaid industries which are generally used to reduce the size of large size rocks into small

More

(PDF) Design and Performance Evaluation of a Stone Crusher

2021.10.7 The fabricated stone crusher was tested and the actual capacity was found to be 301 kg/h with a through-put efficiency of 75.4 %. The crushed products were well

More

(PDF) Consideration the structure formation properties of crusher

2019.6.18 PDF The article is dedicated to the search of ways of decreasing environmental damage from the quarry industry, generating crusher screening.... Find,

More

Experimental study of crushing process of the crushed

2021.2.5 In general, crushed stone production consists of three stages: extraction of raw materials, crushing, and sorting by fractions. Crushed stone is obtained quite simply

More

Simulation and experimental study on the stone powder

2020.3.1 This study is based on computational fluid dynamics (CFD) modelling of gas-solid flow in the VSI crusher, and different air volumes of the induced draft fan are

More

Full-scale model testing of a graded crushed stone sandwich structure ...

2022.12.12 This paper aims to analyse the static and dynamic characteristics of the sandwich structure consisted of an upper ballastless track structure layer, middle graded

More

Experimental and Numerical Studies on Fluid-Structure

2021.12.29 There are two types of crushers depending on how seabed rocks are broken apart: a central-type crusher uses the impact force generated by the free-falling of

More

Aggregate Production Optimization in a Stone-Crushing

2020.2.8 This research involves the optimization of aggregate production using the Taguchi approach to maximize the production rate of Gneiss stone. The L18 orthogonal

More

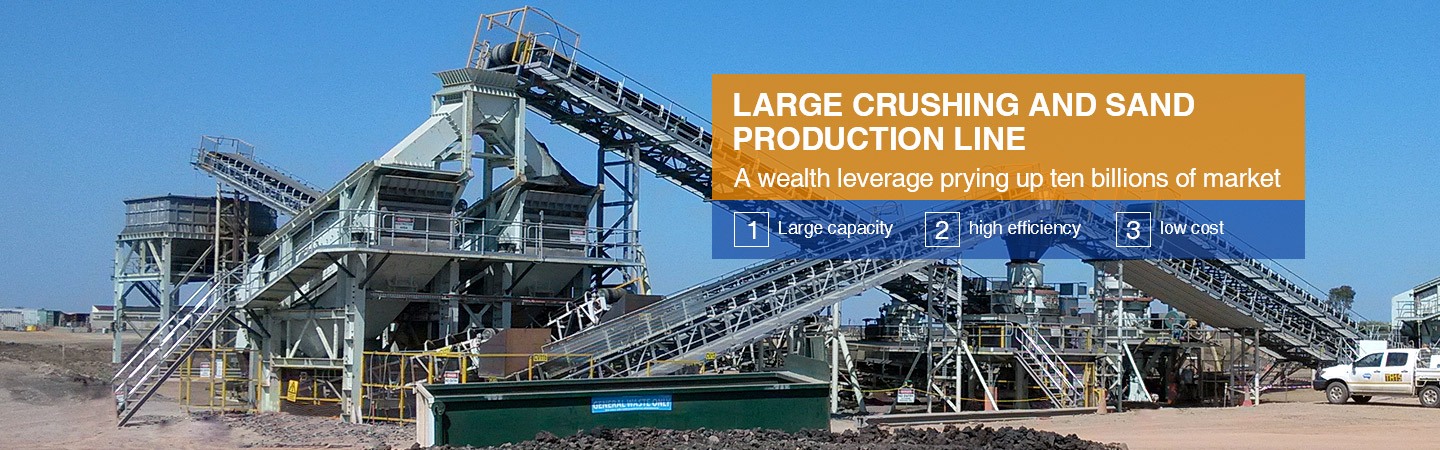

Stone Crusher Cone Jaw Crushers Machine

Belt Conveyor Conveying length: 10m-110m Conveying speed: 1.0-2.0 Capacity: 30TPH-3000TPH The advantages of belt conveyors are a simple structure, a big conveying amount and used widely. The machine is a

More

Effects of stone crushing industry on - ScienceDirect

2011.10.1 According to Deputy Director (Environment), National Productivity Council, New Delhi (Patil, 2001): (i) over 12 000 stone crusher units were operating in India, (ii) stone crushing industry sector had an annual turnover of Rs. 5 000 crores (over 1 billion US $), (iii) this sector provided direct employment to over 500 000 people engaged in various

More

7 Types of Stone Crusher and How to Choose the Best?

2021.9.23 A stone crusher is a type of pulverizer that uses mechanical energy to break blocks of stone, concrete, or other building materials into smaller blocks of a specific grain size. ... It is suitable for a wide range of materials, both soft and hard, especially the coarse and medium crushing of hard stones. Advantages: simple structure, reliable ...

More

Impact crusher structure, working principle and features

2021.9.2 1. Impact crusher structure. 1.1 Impact crushers can be divided into two types according to the number of rotors: single-rotor and double-rotor impact crushers. 1.2 The structure of the single rotor impact crusher (Figure 1) is relatively simple and consists mainly of the rotor 5 (strike plate 4), the impact plate 7 and the machine body. The ...

More

Comprehensive Industry Document Stone Crushers

2018.11.19 The stone crusher is one such industry that exists in the vicinity of almost all major cities/towns throughout the country in all the states because the construction activities go on throughout the country. As transportation of stone over long distances adds to cost of the crushed stone products, the crushers

More

Experimental and Numerical Studies on Fluid-Structure

There are many methods for crushing seabed rock such as a using a free-falling crusher, blasting, and chemical liquid expansion. Blasting and chemical liquid expansion can lead to environmental destruction, noise pollution, and civil complaints. Therefore, a free-falling crusher is generally recommended for use. Understanding the characteristics of a

More

Stone Crushers: A Technical Review on Significant Part of

2022.5.13 2 Concept of Stone Crusher. Stone Crusher is a sort of pulverizer which is utilized to compress or break out assortment of enormous stones. It normally highlights a huge crushing rate and high return and is utilized as an essential equipment in primary, secondary, and tertiary stages of crushing.

More

Hammer Crusher Machine - Big Crushing Ratio And High

Our hammer crusher machine can save the energy more than 50% than the same type of products. This can reduce your running cost. The use of wear-resistant material can reduce the wear of the lining plate and increase the service time. The body of hammer for crusheradopts sealing structure, which well solves the problem of dust pollution and dust ...

More

Crushing - Metso

The crushers are built to perform with the lowest cost per ton, featuring a unique combination of crusher cavity design, crushing forces, reliability and safety. Engineered spare and wear parts as well as maintenance and optimization services are designed with decades of experience in different crushers and crushing processes. The parts are ...

More

Jaw Crusher SpringerLink

2023.6.21 The moving jaw rotates around the eccentric axis as well as swings around the same center (Fig. 2).By removing the moving jaw suspension shaft and the front toggle plate of simple pendulum jaw crusher, and suspending the moving jaw on eccentric shaft to combine the connecting rod and the moving jaw into whole, a compound pendulum jaw

More

VBM STONE CRUSHER PRIVATE LIMITED - Tofler

2022.12.1 The price of financial report of VBM STONE CRUSHER PRIVATE LIMITED prepared by Tofler is INR 799. It is an easy-to-read PDF report on the company that includes five year financial information, ratio analysis, management, group structure, shareholding pattern and more. Subscribe to the Tofler Company360 program for

More

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017.3.4 This kind of impact stone crusher is a kind of hig h-efficient strong coarse and mid crushing . ... Compact structure,high rigid and big ger rotating inertia mass of the totor. 4) ...

More

Difference Between Brick Masonry And Stone

3 天之前 A structure made by placing stone together and bonded with mortar is termed stone masonry. Stone is a natural building material, stones on cut and dressed to the proper shape, they provide an economical

More

How to Start the Business of Stone Crushing - Entrepreneur

Stone crushing plant consists of vibrating feeder, jaw crusher, cone crusher, impact crusher, vibrating screen, belt conveyor and electric control panel etc. Its designed throughput generally is 50-600 t/h. It can be adopted to almost all types of materials from stone production to various ores crushing. Start a Business in Potential Countries ...

More

(PDF) Cone Crusher Performance - ResearchGate

2015.5.13 5.1 Structure of Crusher Analysis ... National Swedish Sand and Crushed Stone. Association (GMF), NCC Baggermanns AB, Nordberg Sweden AB, Råsjö Kross AB, Sabema ...

More

Jaw crushr operate manual: how to install, repair and

2022.9.30 Installation points of the movable jaw. Assemble the movable jaw parts in advance. After assembling the movable jaw, movable jaw shaft, movable jaw plate, toggle pad, etc. on the ground, use a crane or crane to hoist the assembled parts together on the crusher. In the rack. For sliding bearings, it is necessary to grind and match between the ...

More

Stone Crushing Equipment Market Size Analysis Report 2032

Stone Crushing Market Analysis. Jaw stone crushing equipment market size is poised to gain notable traction between 2023 and 2032 owing to their reliability, efficiency, and versatility in various industries. Jaw crushing equipment are increasingly used in construction and other applications to offer ease of maintenance and cost-effectiveness.

More

Stone crusher plant details Henan Deya Machinery Co., Ltd.

2022.4.27 Stone crusher plant details, from A to Z. 1. Background. In recent years, with the development of capital construction around the world, the demand for sand and gravel materials is increasing day by day. In the background of the restriction of river sand mining and the shortage of sand, many places encourage and support the investment for

More

Crusher, Piercer, and Slasher - DnD 5e [Damage]er Feats: A

2022.5.22 Introduction. Introduced in Tasha’s Cauldron of Everything, Crusher, Piercer, and Slasher brought a new collection of options for people who consistently do a physical damage type to add some utility when they do. Each of them gives you a hybrid option for increasing a physical stat, an option to do something once per turn when you

More

MOBILE PROCESSING - Wirtgen Group

3 天之前 crusher is active. The 0-5 mm content of fines produced by the jaw crusher are tolerated by the cone crusher. Jaw crusher: Adjustment of the jaw crusher, see page 181, select acc. to chap. “Setting up jaw crusher”, depending on Desired intermediate product Required performance of secondary crusher Required feed size for the cone crusher

More

Gyratory Crusher SpringerLink

2023.5.11 Gyratory crusher is a crushing equipment that uses the gyratory motion of the crushing cone in the conical cavity inside the shell to extrude, bend, and impact materials, for the purpose of coarse crushing of the materials of various hardness. It was invented in the USA in the 1870s. The equipment specification is usually represented by

More

(PDF) Strength and Durability Aspects of Crushed

2020.6.1 Crusher dust is a fine material formed during the process of comminution of rock into crushed stone or crushed sand. This dust is composed by particles which pass 75 μm BS sieve.

More

Simulation and experimental study on the stone powder

2020.3.1 Using FLUENT software, a coupling model of computational fluid dynamics (CFD) and the discrete phase model (DPM) is used to simulate the airflow distribution and particle traces in a VSI crusher. The stone powder separation and large particle retention performance are evaluated considering two important factors: the structure of the SPS

More

Crushers - All crusher types for your reduction needs - Metso

There are two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation causes, along with the toggle plate, a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of ...

More

Structure of Henan Double Roller Crusher-CSDN博客

2014.3.11 Now, double roller crusher development direction will be as follows: 1, the teeth shape of the toothed plate is no longer used traditional design, bigger tooth shape butt he particle size sure be good, long life, rough toothed plate life of 1.5~2 years, fine toothed plate life not less than 10 months. The shape of the tooth is no longer a fan ...

More

Vibration Diagnosis of Sand Units in a Stone Crusher Plant:

2020.6.24 To understand the artificial sand manufacturing production facilities, we overview the stone crusher plant shown in Figure 1 which includes various manufactural equipment. Stone crushing plays a key role in the reduction of particle size of rocks or stones [8,9,10,11,12,13,14,15,16,17,18,19,20,21]. The jaw crusher is defined as a device

More

crusher是什么意思_crusher的翻译_音标_读音_用法_例句_爱 ...

爱词霸权威在线词典,为您提供crusher的中文意思,crusher的用法讲解,crusher的读音,crusher的同义词,crusher的反义词,crusher ... Its structure and performance - principle of PCH ring - hammer crusher are illustrated. 阐述了PCH型环锤破碎机的结构特点、工作

More

Experimental study of crushing process of the crushed

2021.2.5 Crushers of different designs are used to produce crushed stone: roller, cone, cheek crushers [3-6]. Roll plants crush stone as a result of its crushing. Their structure is based on two horizontal shafts arranged in parallel. They rotate in opposite directions. The feed material passes between the shafts and is crushed into several parts.

More

Crusher, Crushing plant - All industrial manufacturers

jaw crusher BR380JG-3. mobile. Capacity: 50 t/h - 240 t/h. Motor power: 159 kW. Opening height: 1,065 mm. Eco-friendly performance moving to a new stage. The operating weight of the BR380JG-3 ranges from 33,500 to 35,310 kg, with a

More